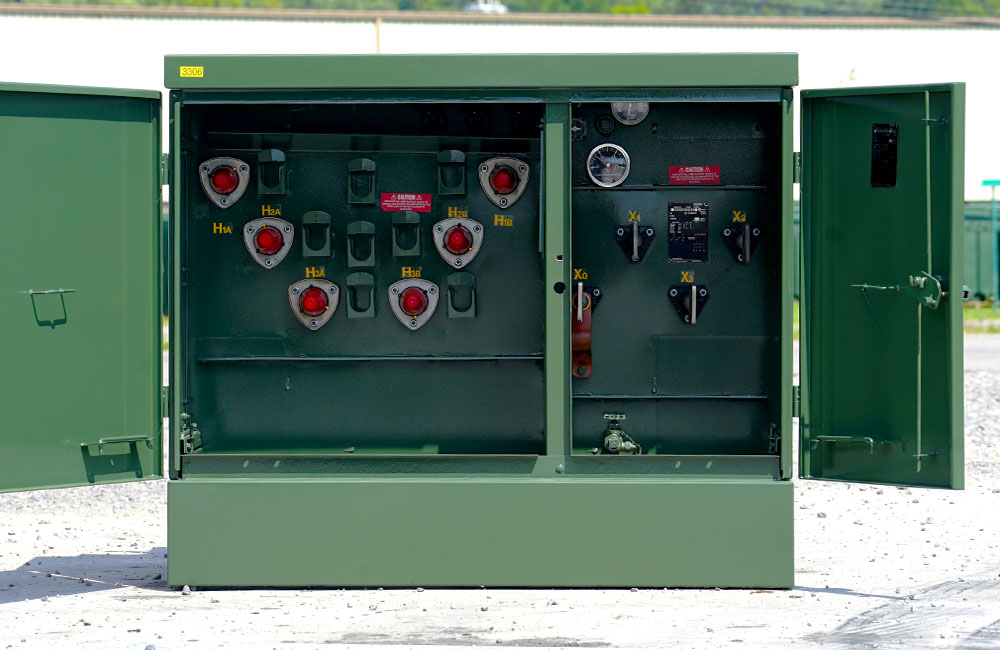

Padmount Transformers

5 MVA / 34.5 kVA and below

The tamper-proof go-to choice for commercial, industrial, and utility projects or buildings - designed to withstand various types of environments, both indoor and outdoor.

SOLUTIONS FOR ALL OF YOUR PROJECT NEEDS.

Engineered Padmounts

When specs are most important.

Whether you are ordering a cup of coffee or 2500 kVA Padmount, JCL understands custom solutions are in high demand. Our “Made to Order” (MTO) process is tailored to be thorough (on specs) and simplistic (on buying + terms).

We understand the pressure of getting it right to meet utility or developer requirements. If the answer to any of the questions below are yes, then JCL Engineered Padmounts are for you!

- Waiting 12-18 months for custom padmounts?

- Experiencing poor service / engineering support?

- Struggling to get specs correct?

- Specs have been correct, but quality is jeopardized?

- Days or weeks in-between responses?

We still believe that the customer should get exactly what they paid for. Relying on quality product and service while operating with a sense of urgency we here to be a true partner on your engineered product needs.

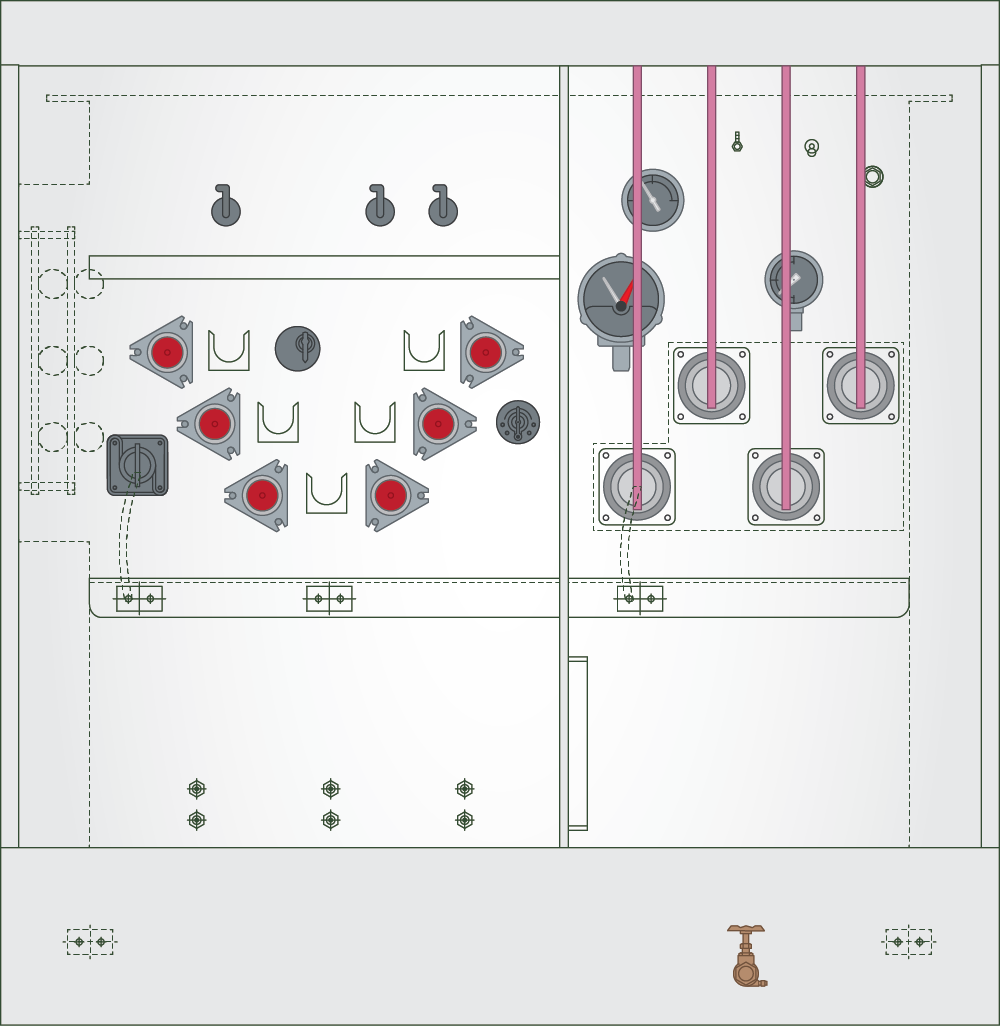

Bay-O-Net Fusing

Designed to provide overcurrent protection, Bayonet fuses interrupt the electrical circuit in case of a fault, such as a short circuit or excessive current flow. When a fault occurs, the bayonet fuse melts or blows, breaking the circuit and preventing damage to the transformer and other connected equipment.

On / Off SwitchOn / Off Switch

Also known as a load break switch or a disconnect switch, it controls the electrical connection to the transformer. This switch provides a means to manually connect or disconnect a transformer from a power source or distribution system - utilizing a handle or lever mechanism that allows operators to manually open or close the electrical circuit.

HV Neutral BushingH0 Bushing

Also known as an HV Neutral Bushing, they are typically positioned on the transformer tank and provide a crucial and secure connection point for the neutral conductor of a transformers high voltage winding.

HV BushingHV Bushing

Designed to provide a controlled passage for electrical conductors, typically carrying high-voltage currents, into and out of a transformer. High voltage bushings serve as an insulating barrier between the internal components of a transformer and the external environment - such as moisture, dust, and contaminants.

Tap Changer5-Position Tap Changer

Regulating the output voltage of the transformer, it allows for the adjustment of turns ratios, effectively changing the voltage ratio between primary and secondary windings. Crucial for maintaining a consistent output voltage under varying load conditions or when faced with fluctuations in input voltage.

Current Limiting FuseCurrent Limiting Fuse

Designed to rapidly interrupt an electrical circuit during overcurrent events, these fuses limit the magnitude of short-circuit currents - minimizing stress on equipment and reducing potential damage. In the event of an overcurrent or short circuit, it acts promptly to interrupt the flow of electrical current. This swift interruption is essential for minimizing the impact of the fault.

Arrester ProvisionsArrester Provisions

An integrated mounting bracket / support meant to securely attach surge arresters and strategically located to optimize the effectiveness of the surge protection system. Their placement ensures that surge arresters installed can promptly divert excessive voltage away from a transformer.

Two-Hole Ground PadTwo-Hole Ground Pad

A grounding feature with strategically located holes on the transformers exterior, typically near the base or on the transformer tank. Designed to accommodate grounding conductors or cables, meant to provide a secure grounding connection to a transformer for directing fault currents to the ground.

Terminal BlockTerminal Block

Strategically located for easy access during installation and troubleshooting, it serves as a junction point for various wires and cables. Featuring secure fastening mechanisms to prevent accidental disconnection, it includes multiple connection points for terminating incoming and outgoing conductors.

Drain ValveDrain Valve

Typically located at the bottom of the transformer tank, to allow gravity-assisted drainage, drain valves provide a means for draining or removing accumulated moisture or oil from a unit. Typically constructed from materials to allow for reliable operation even in challenging environmental conditions.

Pressure Relief ValvePressure Relief Valve

A safety device designed to safely release internal pressure - such as temperature variations, internal faults, or changes in the volume of insulating oil - that could lead to a catastrophic failure of a transformer tank.

Liquid Level GaugeLiquid Level Gauge

Utilizing a float mechanism within the transformer tank, it monitors and displays the level of insulating liquid, usually oil, within the transformer. Crucial for ensuring that the transformer is adequately immersed in oil, preventing overheating and maintaining effective insulation.

Pressure GaugePressure Gauge

Equipped with a pressure sensing mechanism, such as a diaphragm or Bourdon tube, it measures and displays the internal pressure of the transformer tank. It is calibrated for safe operating pressure ranges, as deviations may indicate abnormal conditions or issues that need attention.

Temp GaugeTemperature Gauge

Typically installed on the transformer tank, the temperature gauge monitors and displays the transformer's operating temperature. It ensures a transformer operates within safe temperature limits, as excessive temperatures can lead to insulation degradation and impact its performance and lifespan.

LV Bushing SupportLV Bushing Support

Structural component, which can include mounting brackets or flanges, designed to provide support and secure positioning for low voltage bushings.

LV Neutral BushingX0 Bushing

Also known as an LV Neutral Bushing, they are typically positioned on the transformer tank and provide a crucial and secure connection point for the neutral conductor of a transformers low voltage winding.

LV BushingLV Bushing

Mounted on the transformer tank, they act as an interface between the transformer and the external low voltage distribution system - providing access points for the connection of low voltage conductors.

PROUDLY COMPLIANT WITH

Example Timeline

JCL understands that on-time delivery is critical to a successful energization. Our commitment is steadfast on doing what we say we’ll do; however, purchasing engineered products is a team effort. We rely on complete specifications and expeditious review / approval of drawings. These are crucial to maintaining on time delivery dates. Below is the normal cadence of an order.

-

1

Request for Quote (RFQ)

1 week

-

2

Quote Review / Q&A

1 week

-

3

PO / Order Entry

1-2 Days

-

4

Approval

Drawings2-3 weeks

-

5

Production

30-34 weeks

-

6

Delivery

2-5 days

Markets We Proudly

JCL Padmounts span all emerging and traditional markets. We’ll build to your custom specifications for step-up or step-down requirements.

In-Stock Padmounts

When lead time is most important.

We are investing in the modernization and energization of American industry. JCL offers the largest inventory of three-phase Padmounts in the entire country - with literally hundreds of new in-stock units, ready to be put on trucks and satisfy any sense of urgency, or deadline, you have.

We commonly stock anything in the following ranges:

kVA Range 300 - 5000 kVA

Primary Voltage 5kV - 35kV

Secondary Voltage 208 - 15kV

Our Inventory of Padmount Transformers

Often customers are in disbelief with our availability of Padmounts. Our unwavering commitment is to meet our customer’s needs – that means investing in new inventory. We understand that waiting weeks, months, or even years for products is just not feasible for many jobs. Our inventory is for those projects; the ones with energization deadlines, the ones just waiting on a transformer, the ones where another vendor has failed you.

Reconditioned Padmounts

When price is most important.

Just because a transformer comes out of service or was having issues while energized does not mean its scrap. The JCL team takes great pride in offering an environmentally sustainable option to sourcing Padmounts.

JCL reconditioned transformers must pass our stringent procurement and reconditioning process before they are suitable for sale in the market. When completed, reconditioned transformers are a fantastic alternative for a more price-sensitive application that requires a prompt delivery.

Reconditioning Timeline

When operated and cared for properly, transformers can operate for numerous decades. All JCL reconditioned units go through a scrutinous acquisition and reconditioning process - highlighted below - before they deliver to our customers. Reconditioned transformers are environmentally sustainable, and cost / time effective options.

-

1

Inspection

Thorough overview of work to be completed.

-

2

Replace / Modify

Gauges, fuses, valves, etc to ensure safe and long lasting operation..

-

3

Powerwash / Paint

Methodically sand, clean, and apply coat of water based paint.

-

4

Testing

TTR, Megger, Resistance (and Power Factor if applicable.

-

5

QC / Final Review

Meticulously inspect and photograph before shipment.

-

6

Shipment

Off to you and its brand new home!

Before & After

Like restoring a vintage truck or house – Padmounts can go the distance when reconditioned. With new fluid, new bushings / components, new paint, and all cosmetic defects removed we go the extra mile to ensure you’ll be proud to have a reconditioned JCL transformer on your property.

Or contact a Transformer Specialist at 866-983-1300. We offer quick quote returns, fair pricing and speedy lead-times!